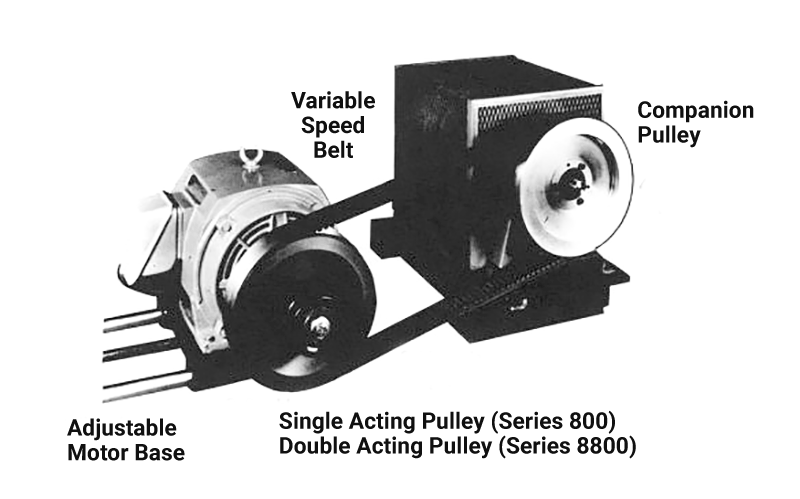

Adjustable Center Drives – Series 800 & 8800

Adjustable center drive packages consist of four drive system components: a spring-loaded pulley mounted on the motor shaft, a fixed diameter companion sheave mounted on the driven shaft, a variable speed belt running between the pulley and sheave, and a sliding motorbase upon which the motor is mounted.

Typically these drives are used for output speed reduction such that a 1:1 ratio exists between the motor and driven shafts, when the belt is set at the highest possible pitch diameter on the spring-loaded driver pulley, and the center-distance between the motor shaft and driven shaft is at its minimum (shortest) distance.

Output speed is changed by turning the handwheel on the sliding motorbase, which moves the motor closer or further from the driven shaft, and allows the belt to a lower pitch diameter on the spring-loaded driver pulley.

Series 800 – One Side Moveable

![]() Model 816

Model 816![]() Model 827

Model 827

![]() Model 859

Model 859![]() Model 810

Model 810

![]() Model 821

Model 821![]() Model 833

Model 833

Series 8800 – Two Sides Moveable

![]() Model 8816

Model 8816![]() Model 8827

Model 8827

![]() Model 8813

Model 8813![]() Model 8810

Model 8810

![]() Model 8823

Model 8823![]() Model 8821

Model 8821

![]() Model 8833

Model 8833![]() Model 8854

Model 8854

![]() Model 8843

Model 8843![]() Model 8899

Model 8899

![]() Model 8859

Model 8859

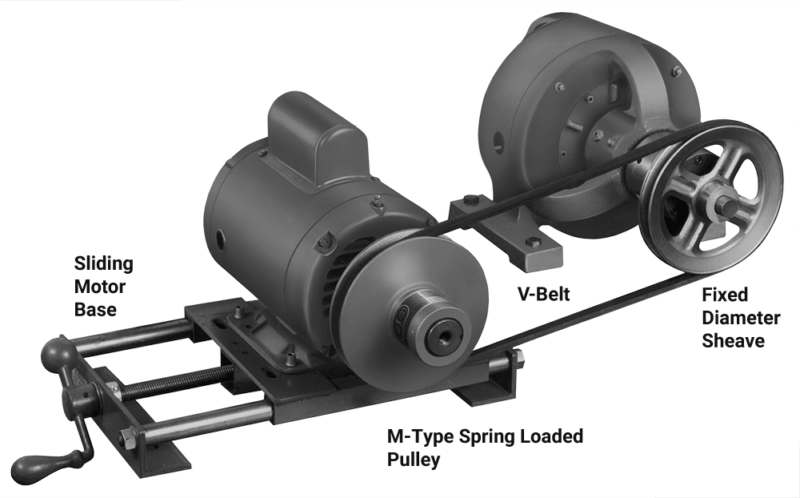

Adjustable Center Drives – Series 21

- Standard V-Belt Drives

- Adjustable Center

- Permanent Lubrication

- 1/4 to 4 H.P.

Series 21, Spring Loaded Pulley

![]() Series 21 – 3M

Series 21 – 3M

![]() Series 21 – 4M

Series 21 – 4M

![]() Series 21 – 5M

Series 21 – 5M

![]() Series 21 – 6M

Series 21 – 6M

![]() Series 21 – 7M

Series 21 – 7M

![]() Series 21 – 8-1-M

Series 21 – 8-1-M

Checklist for Drive Selection

Determine Motor Speed and Horsepower

- Series 800 & 8800 – Select the drive that satisfies these conditions.

- Series 21 – Select the range of Fixed-Center drive combinations which fall into your requirements.

Determine Driven Shaft Speeds Required

- Series 800 & 8800 – Select the proper diameter companion pulley for the chosen drive

- Series 21 – Select the combination from the range you have selected which best fits your speed range.

Determine Center Distance Between Motor and Driven Shaft

- Series 800 & 8800 – Select the proper belt by refering to the belt vs. center distance chart

- Series 21 – Select the proper belt by refering to the belt vs. center distance chart on your chosen combination.

Determine Motor Frame Size – Series 800 & 8800 Only

- Select the proper motor base

- Select the motor base configuration you will use (Series 800 only)

- Select the proper bore for your pulley by using NEMA standards

Check Your Power Requirements at The High and Low Speeds – Series 800 & 8800 Only

- Compare your requirements with the rated power curve

Determine Motor and Driven Shaft Diameters – Series 21

- Refer to the dimensional data for your selected pulleys and confirm that the shaft diameters are within the pulley’s design limitations.