Series 21- Compound Drives

- Low Output Speeds

- 2 Standard V-Belts

- Fixed Centers

- High Ratio to 9:1

- Cam-Actuated Control Insures Belt Alignment

- Spring-Loaded Pulley Insures Proper Belt Tension

- 1/4 to 1-1/2 H.P

Unique Design Advantages

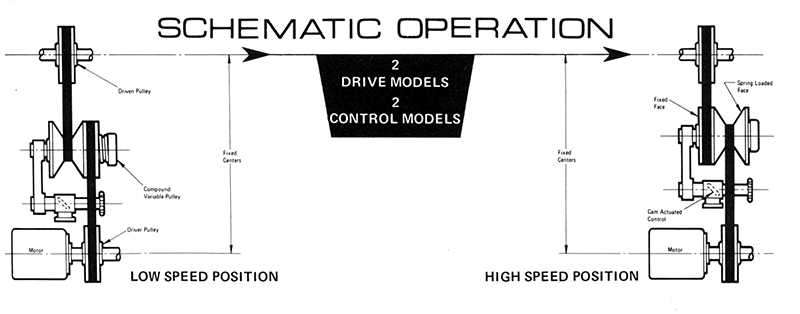

The Speed Selector design of Compound-type standard V-belt pulleys offers advantages not available from any other manufacturer.

The first advantage of our design is that one of the belt faces is spring-loaded to assure proper belt tension on both belts throughout the entire speed range.

This exclusive feature enables the drive to carry its full rated capacity at all speeds and eliminates the need for any additional means of belt take-up. In common countershaft drives without this automatic tension control, the belts become loose in some speed positions causing loss of power capacity and short belt life due to slippage under load.

The second advantage of our design is to be found in the control mechanism.

Positive belt alignment and speed control are built into the Speed Selector control. This superior control design adjusts the speed by swinging the countershaft in an arc around its mounting and by means of a cam adjusts the sheave assembly along its axis to maintain belt alignment in all speed positions. This feature makes vertical shaft installations thoroughly practical. The simple sturdy control is free operating, yet self-locking and may easily be adapted to remote operations.

The third advantage is that Speed Selector Compound pulleys offer high speed ratios with the use of standard A section belts.

Ratios of up to 9: 1 are available. The Compound Drive varies the speed in equal ratios above and below the speed which would be obtained from the fixed sheaves alone. (In the case of a 9: 1 ratio drive the output speeds would vary 3: 1 above and below the speed available from the fixed pulleys.)

Checklist for Drive Selection

Determine Motor Horsepower @ 1800 RPM and Output Speed Required

- Use the Horsepower Ratings vs. Output Speed chart (on each drive model page) to select the correct motor & pulley diameters which give the proper output speed.

Determine the Center Distance Between Motor and Driven Shaft

- Select the proper belt from the Belt vs. Minimum Center Distance chart which allows the variable pulley to fit within the overall center distance. Belts are selected according to the diameters motor and driven pulleys to be used.