An Introduction to Variable Speed Pulleys and How They Work

A Variable Speed Pulley is a device for changing the speed of a rotating shaft member, so that it will increase or decrease the revolutions per minute of that particular shaft. The belt used in the pulley has a ‘V’ cross section, where the sides of the ‘V’ conform to the angular faces of the pulley flanges. As the flanges of the pulley open or close, the belt will be forced either up or down in the pulley, producing a larger or smaller working pitch diameter which in turn will increase or decrease the revolutions per minute of the shaft upon which the pulley is mounted.

Usually two pulleys are mounted on separate shafts, one called the driver shaft which is always the power source, such as an electric motor, the other called the driven shaft which is the unit where the speed variation is required. The belt is simply the medium used to transfer the power from the power source to the driven unit. The power transmitting capacity of the belt is achieved by frictional grip, which is the wedge action of the belt between the pulley faces.

There are Basically Two Types of Systems in Use:

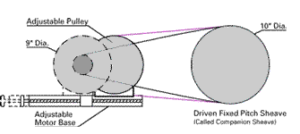

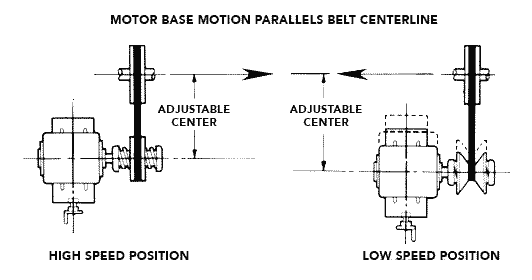

The Adjustable Center Type Drive

The adjustable pulley is spring loaded, the spring being the medium used to keep tension on the belt for maintaining the frictional grip. As the pulley, mounted on the motor shaft is forced away from the driven fixed pitch sheave by the screw action of the adjustable motor base, the belt is forced to ride on an ever decreasing pitch diameter, constantly slowing the speed of the driven pulley, until the required speed is reached.

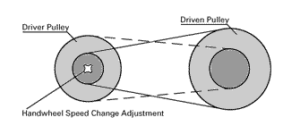

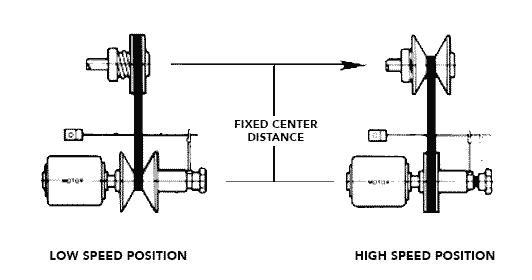

The Fixed Center Type Drive

Here, both pulleys are adjustable, the driven pulley being spring loaded, the driver pulley mechanically variable by means of an adjusting screw and nut. The action of turning the screw in the driver pulley will open the faces, allowing the belt to ride lower between the vees. The spring in the driven pulley will then force the belt to ride higher in that pulley, as the flanges are forced closer together. This will decrease the speed of the driven pulley. When the action is reversed by turning the screw in the driver pulley in the opposite direction, thereby allowing the pulley faces to close, the reverse will apply, and the speed of the driven pulley will increase. In this type of drive, the driver and driven shafts are in a fixed position. They can only rotate, not move in any other direction.

Engineering Detail on Variable Speed Pulleys

For further, specific information regarding applications, load carrying capacities and formulas to determine optimal implementation – download the Speed Selector Engineering Guide.